Predictive Maintenance: The Key to Moving Your Equipment Forward

Businesses perform routine maintenance necessary for the smooth operation of their equipment. However, maintenance before a breakdown often plays a limited role in improving the performance and life of an equipment. Predictive maintenance is a maintenance strategy aimed at minimizing the risk of failure in order to maximize the life of equipment. Predictive maintenance is a maintenance approach used to prevent unplanned failures of machinery or equipment. This approach allows predicting machine failures and performing preventive maintenance. It also allows us to collect and analyze real-time data about the current state and operating conditions of an equipment. This data is used to determine which parts of a piece of equipment need to be replaced or repaired and when. Predictive maintenance that allows to diagnose machine failures before they occur and to take preventive measures; In addition to extending the life of equipment, it can provide many benefits such as increasing production times, improving product quality and reducing operating costs.

The main purpose of predictive maintenance is to collect, analyze and interpret data to understand and prevent the causes of machine failures. This approach helps prevent breakdowns and reduce maintenance costs, while extending the life of the equipment. Predictive maintenance is a type of planned maintenance and allows businesses to maintain with less downtime and less cost while minimizing the risk of failure. Therefore, predictive maintenance; It is widely used in manufacturing plants, automotive, aerospace and many other industries.

Predictive maintenance consists of four main elements:

Real-time data collection: Data collected from equipment is used for early diagnosis of faults. This data can be collected through sensors, smart devices and other technologies.

Data analysis: Data is analyzed to provide information about the health of an equipment. These analyzes are used to decide which parts of a piece of equipment should be replaced or repaired and when.

Maintenance planning: As a result of the analysis of the data, it is decided which preventive measures will be taken. This allows for better management of equipment and more accurate planning of maintenance.

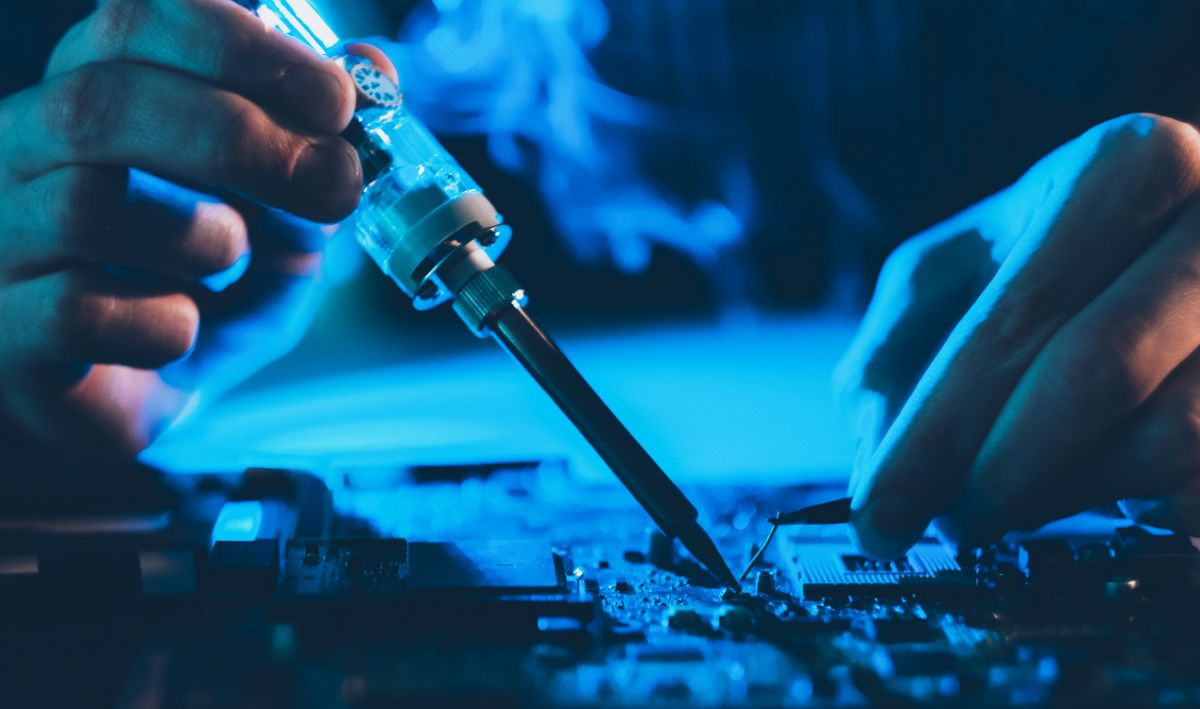

Implementation of maintenance: According to the maintenance plan, preventive maintenance is carried out. This may be parts replacement, cleaning, lubrication or other operations.

For predictive maintenance to be successful, it is important to collect the right data, analyze it correctly, and perform preventive maintenance at the right time. Therefore, predictive maintenance requires the use of high-quality sensors, measuring equipment and data acquisition devices. As a result, predictive maintenance helps prevent breakdowns and reduce maintenance costs while extending the life of machinery and equipment. This approach includes data collection, analysis, maintenance planning and implementation steps. Proper implementation of these steps ensures successful predictive maintenance.